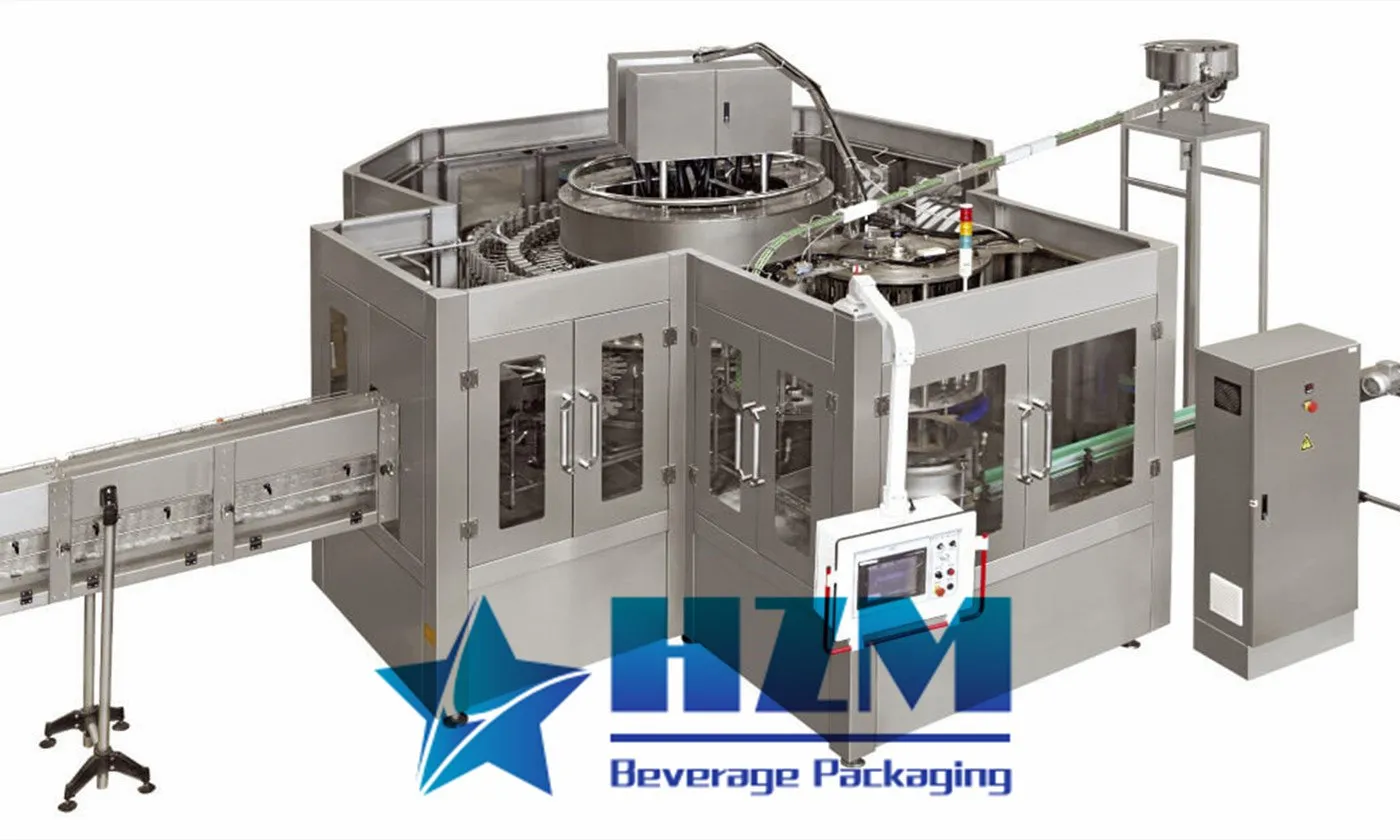

The olive oil bottle filling machine primarily finds its application in the production lines of edible oils and condiments. Typically, it employs flowmeter and weighing-based filling methods, offering several advantages such as remarkable precision, zero dripping or leakage, and extensive automation capabilities. This versatile machine is designed to accommodate various bottled olive oils, condiments, and other related products, with production capacities ranging from 2,000 to 20,000 bottles per hour, based on a 500ml volume.

This olive oil filling machine is designed for precise filling and capping of a wide range of edible oils. The functions of the olive oil bottle filling machine include: disinfection and cleaning, automatic filling chain control, feeding liquid level, material temperature control, and pneumatic conveying (or screw conveying) of the feeding bottle.

Olive oil filling machines are automated machines specialized in filling olive oil and are commonly used in the food processing industry and by olive oil manufacturers. These machines are designed to increase productivity and ensure product quality and consistency while reducing the need for manual labor. Increased productivity, product quality and consistency. They are indispensable automation equipment for the food processing industry, helping to meet market demands and ensuring the high quality of olive oil manufacturing.

Operation of the olive oil bottle filling machine is controlled by advanced HMI, it realized the communication with man and machine. Function of control system is followed: product speed control, automatic stop with fault and take count of output and so on.

Most of the accessories of our olive oil bottle filling machine are imported. If you need to customize the accessories or functions of theolive oil filling machine, you can contact our engineers for professional communication~

Home /

Home /